Get everything done

in house with Lumel Alucast

Product

development

Lumel Alucast engineering team active cooperates with customers in area of product development, beginning from construction works, technological improvements to the selection of production processes, allowing for cost optimization

and quality improvement of the final product.

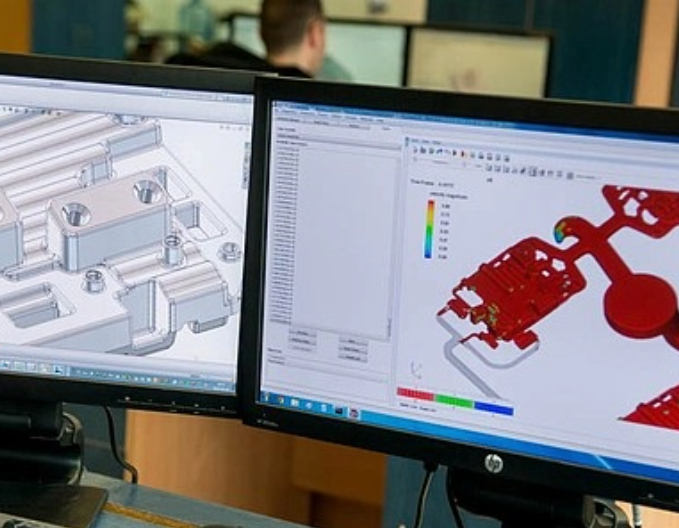

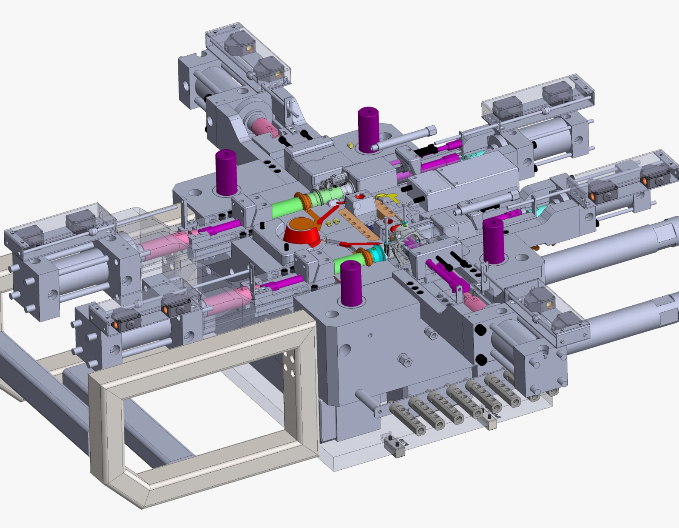

Tool design

Lumel Alucast tool shop has its own engineering team, that creates construction and technological documentation for tool processes.

Our constructors team designs the tools based

on 3D drawings or on entrusted documentation.

We specialize in designing of tools in the area

of HPDC like: moulds, dies, gating systems working in full automatic casting cycle, CMM

and CNC fixtures.

Tool shop

Lumel Alucast tool shop carries out all works connected with execution of moulds, dies

and machining fixtures. We prepare

40 sets of tools for our customers every year.

We can manufacture the tools with the maximum dimensions (X) 1000 x (Y) 500 and weight up to 500 kg. We use such machining processes like: milling, turning, drilling, grinding and EDM.

Due to documentation prepared by our engineer’s team, Lumel Alucast tool shop executes the tools and fixtures like:

• elements for casting moulds,

• trimming dies,

• CNC and CMM fixtures,

• spare parts like forming pins, mould forming elements (cores, sliders, inserts).

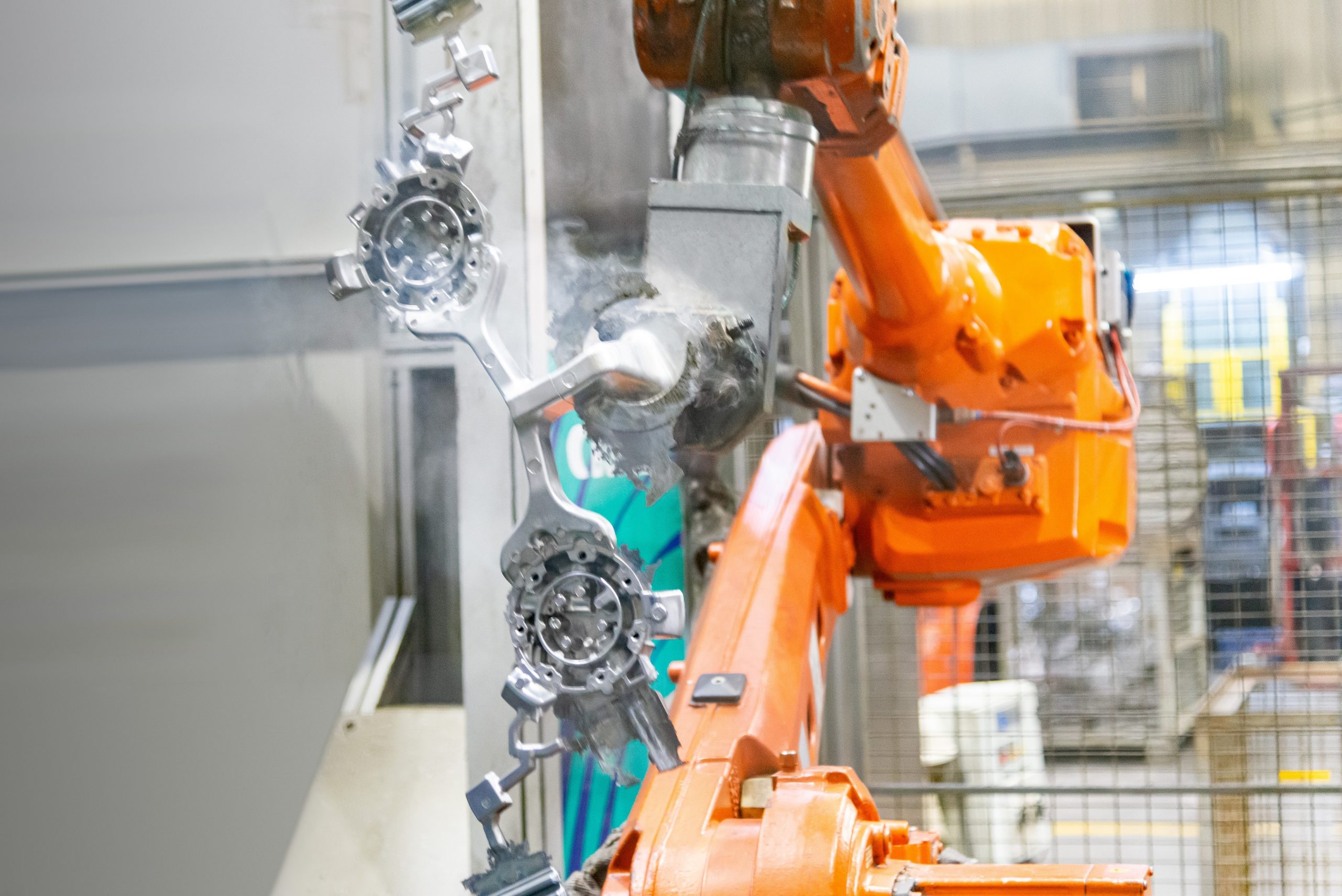

Die-casting

We melt 20 tones of alloys every year.

We specialize in production of high pressure

die-castings from aluminium alloys EN AC-47000, EN AC-46000, EN AC-44200 and EN AC-43400, ADC12. We use machines with closing force

from 400 to 840 tones. Our castings fulfill explosion-proof requirements (EX). We have

the possibility to manufacture die castings

from 0.3 kg up to 6 kg.

CNC machining

We cover complete spectrum of CNC machining complemented by the latest technologies,

what allow us to guarantee the quality, precision

and repeatability of manufactured parts.

Surface

treatment

Aluminum treatments give the material surface the proper efficiency in industrial applications.

By using operations like shot blasting, chromate coating, anodizing or painting we can significantly increase the quality and value of your product.

Pre-assembly

We have the possibility of assembling

of standardized and customized elements

as well as elements executed in our factory.

To the assembly we use mechanical,

electrical components and circuit boards

executed in SMT or THT technology.

Electronic assembly

Aside from aluminium die-casting business

for nearly 70 years Lumel is well-known

for the production of highest quality of electronic measuring devices. For the customers, who want to have 100% product ready to sell we offer following services:

• EMS – electronic manufacturing services

• OEM / ODM – Conceptualizing – Designing – Development – Production, in the scope

of housing, electronics, mechanics and software.

All under one roof.

Contact

ul. Słubicka 1

65-127 Zielona Góra | Poland

(+48 68) 45 75 100

lumel@lumel.com.pl

Lumel Alucast Sp. z o.o.

Bank account: ING Bank Śląski S.A.

PL77 1050 1520 1000 0024 1732 7711 (EUR)

PL76 1050 1520 1000 0024 1732 7729 (USD)

SWIFT: Code INGBPLPW

Registered in District Court in Zielona Góra, VIII Economic Department

of Domestic Court Register under No. KRS 0000381491

NIP 527-265-14-70

Initial capital: 5 916 600 PLN

© 2021 | Copyright by LUMEL ALUCAST Sp. z o.o.